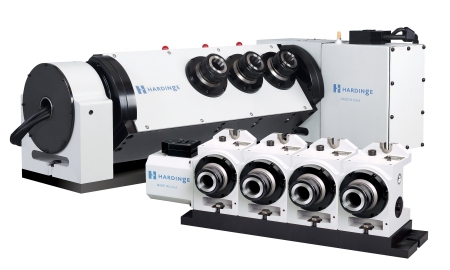

Hardinge Group, the world’s largest manufacturer of spindle tooling, announces the release of the 80mm FlexC™ vulcanized collet system. The collet chucks mount directly to the machine spindle. The 80mm vulcanized collets are inserted and removed with a manual compression wrench for collet changeover in less than ten seconds. That’s 8x faster than it takes to change a collet in a standard collet chuck and 19x faster that it takes to change three jaws on a jaw chuck.

Hardinge Group, the world’s largest manufacturer of spindle tooling, announces the release of the 80mm FlexC™ vulcanized collet system. The collet chucks mount directly to the machine spindle. The 80mm vulcanized collets are inserted and removed with a manual compression wrench for collet changeover in less than ten seconds. That’s 8x faster than it takes to change a collet in a standard collet chuck and 19x faster that it takes to change three jaws on a jaw chuck.

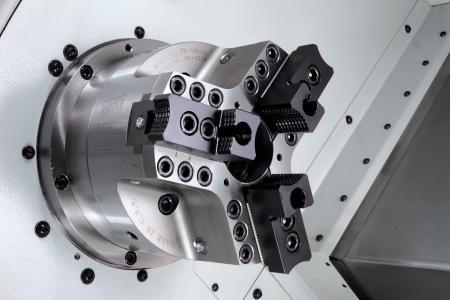

But quick changeover is not the only benefit of this system. The FlexC collet system falls in the “special accuracy” collet classification having guaranteed accuracy within .0004″ (.010mm) TIR for style A (pull-back Dead-length® stationary stop) and .0008″ (.020mm) TIR for style DL (push-to-close). These systems achieve the same gripping capability as conventional collets while using less draw bar force. Additionally, the all too frequent variation in bar stock will no longer be a hindrance. The collet head has a gripping range of ±.020″ (.5mm) of its nominal size to allow for variation in bar stock without having to change the collet. Because there is no collet body, the collet segments will remain parallel to the stock even when there are variations in the bar stock. This parallel clamping insures full bearing contact with the part for optimum holding power and reduced push back.

The Hardinge FlexC collet system is an ideal substitute for 3-jaw chucks because it weighs less, has a lower profile and changes over much faster. Hardinge FlexC collet systems are interchangeable with other brands on the market. Consider the FlexC collet system over other conventional collet adapters to meet special accuracy requirements, or mount it on a chuck-style lathe or rotary indexer for increased versatility. Collets are available in round and hex smooth, round and hex serrated, square smooth, emergency and S-master styles.

For more information contact Hardinge via workholding@hardinge.co.uk or visit http://www.shophardinge.co.uk

Posted by HardingeUK

Posted by HardingeUK